What material are Industrial Bus Slip Rings made of?

Industrial Bus Slip Rings are typically made of copper or aluminum, as these materials provide excellent electrical conductivity and durability. However, the specific material used mayvary depending on the application and manufacturer. Some slip rings may also be made of stainless steel or graphite for added corrosion resistance or high-temperature performance.

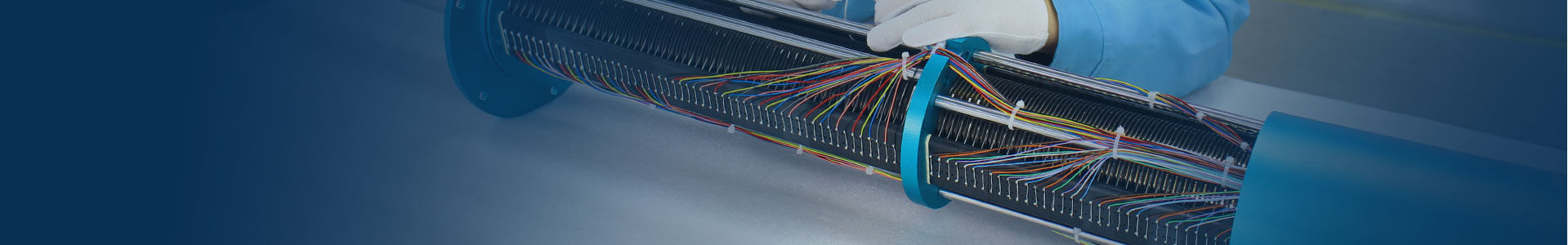

Industrial bus slip rings are designed to transmit data and signals across various industrial communication protocols while enduring harsh operating conditions. These slip rings are typically

constructed using materials chosen for their electrical properties, durability, and resistance to environmental factors. Common materials used in the construction of industrial bus slip rings include:

1. Conductive Rings and Contacts:

Gold: Gold is frequently used due to its excellent electrical conductivity, corrosion resistance, and reliability in maintaining signal integrity, especially for carrying digital signals found

in industrial bus communication.

2. Insulation Components:

Engineering Plastics (e.g., Polyamide, PTFE): These materials provide electrical insulation between conductive elements, mechanical support, and protection against environmental

factors without compromising signal fidelity.

3. Housings and Enclosures:

Aluminum: Lightweight and resistant to corrosion, aluminum is commonly used for the housing and casing of industrial bus slip rings.

Stainless Steel: Employed for enhanced durability and resistance to harsh industrial environments where corrosion resistance is paramount.

4. Contact and Bearing Materials:

Precious Metal Alloys: Slip rings may incorporate precious metal alloys such as palladium or platinum for contact materials to ensure consistent and low-wear electrical connections vital

for preserving signal integrity.

Ceramic Bearings: Used to provide low-friction and wear-resistant properties, especially in high-speed applications.

5. Coatings and Finishes:

Electroless Nickel Plating: Applied to certain components to enhance corrosion resistance and wear properties, thereby ensuring long-term reliability in demanding industrial settings.

By leveraging these materials, Through Hole Slip Ring can maintain reliable transmission of digital signals across various industrial communication protocols while withstanding the rigors

of industrial environments, including temperature variations, moisture, contaminants, and mechanical stress.

For more details on Through Hole Slip Ring products, please view :https://www.senring.com/through-hole-slip-ring/larger-hole/h100185.html

FAQ questions:

1.What is the difference between a rotary joint and a rotary union?

2.What would be the effect of using a slip ring instead of a split ring commutator?

3.What are the limitations of Pancake Slip Rings?

4.What are the purpose of slp ings on rotor?

5.What is capsule slip ring and is used for?

- Are Industrial Bus slip rings usually made of copper?

-

- 24-01-2024

- Yes, Industrial Bus slip rings are usually made of copper. Industrial Bus slip rings are not typically made entirely of copper. Instead, they often feature cop

- more+

- What are the application fields of industrial bus slip rings?

-

- 11-12-2023

- The industrial bus slip ring is an electrical component responsible for connecting and transmitting energy and signals to rotating bodies. According to the tran

- more+

- What material are Industrial Bus Slip Rings made of?

-

- 22-02-2024

- Industrial Bus Slip Rings are typically made of copper or aluminum, as these materials provide excellent electrical conductivity and durability. However, the sp

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE