What are the limitations of Pancake Slip Rings?

The limitations of Pancake Slip Rings include:Limited space for components, which can restrict the number of circuits and capabilities.

Reduced ability to handle high power and current due to size constraints.

Potential for decreased mechanical robustness compared to larger slip ring designs.

Limited options for customization and integration of additional features due to compact design

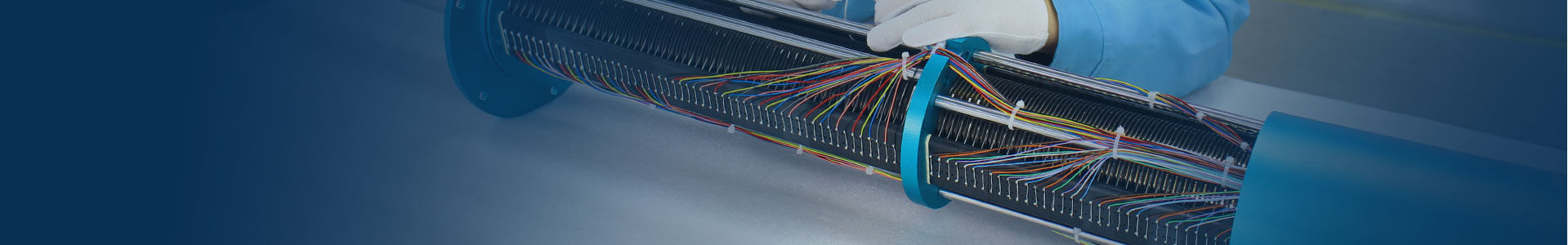

Pancake Slip Rings are a type of electrical connector used to transfer power and data between rotating and stationary parts of a device. While they are commonly

used in various applications, they also have some limitations, including:

Wear and Tear: Pancake Slip Rings are subject to wear and tear over time due to the continuous rubbing of the contacts. This can lead to reduced performance and eventual failure

of the component.

Limited Speed: Pancake Slip Rings have a limited speed range, beyond which they may not be able to maintain a reliable connection. The speed limit varies depending on the design

and size of the slip ring.

Limited Current Capacity: Pancake Slip Rings industrial have a limited current capacity, which means they may not be suitable for high-current applications. Exceeding the rated current can cause

overheating and damage to the slip ring.

Environmental Factors: Pancake Slip Rings are sensitive to environmental factors such as temperature, humidity, and contaminants. These factors can affect the performance and lifespan

of the slip ring.

Size and Weight: Pancake Slip Rings can be relatively large and heavy, which may be a limitation in applications where space and weight are critical factors.

Cost: Pancake Slip Rings can be expensive, especially for high-performance designs. This cost may be a limiting factor in some applications.

For more details on slip ring products, please view :https://www.senring.com/info/industry/2023-12-28/107.html

FAQ questions:

1.Does wound rotor motor need slip ring and brushes?

2.Why do we use carbon brushes in high speed slip ring motor?

3.What would be the effect of using a slip ring instead of a split ring commutator?

4.What are the purpose of slp ings on rotor?

5.How do you increase the torque of a slip ring induction motor?

- What is Pancake Slip Rings?

-

- 06-03-2024

- Pancake slip rings, also known as flat slip rings, are specialized electrical devices used to transmit power, electrical signals, or data across rotating interf

- more+

- What are the limitations of Pancake Slip Rings?

-

- 05-02-2024

- The limitations of Pancake Slip Rings include: Limited space for components, which can restrict the number of circuits and capabilities. Reduced ability to ha

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE