How do you increase the torque of a slip ring induction motor?

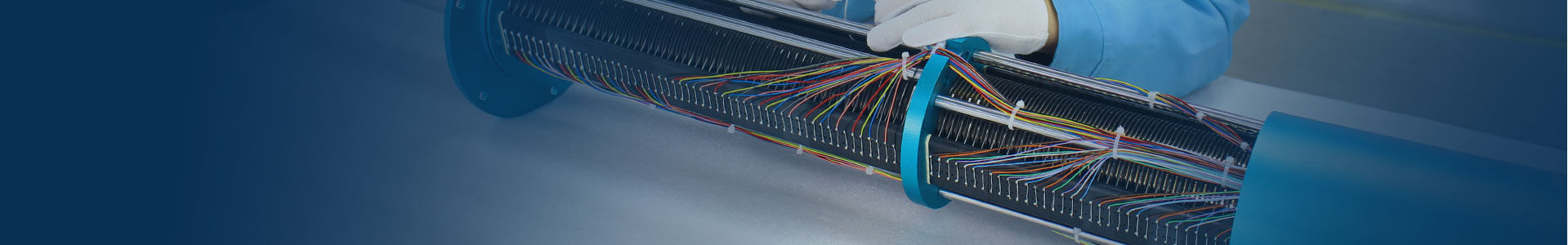

You can increase the torque of a slip ring induction motor by increasing the number of turns on the stator winding.Increasing the torque of a rotary electrical slip rings induction motor can be achieved through several methods and modifications targeted at optimizing its performance. Here are some key approaches to

enhance the torque output of a slip ring induction motor:

1. External Resistance:

Rotor Circuit Modification: Adding external resistance to the rotor circuit through a variable resistor or other means can increase starting torque while reducing starting current. This can be

achieved by inserting resistance into the rotor winding through slip rings and brushes, allowing for improved torque characteristics.

2. Deep Bar Rotor:

Retrofitting the Rotor: Redesigning the rotor with deeper rotor bars can increase the torque capability of the motor, enhancing its ability to handle higher loads and providing improved starting torque.

3. High Resistance Rotor Material:

Rotor Winding Materials: Using high-resistance materials in the rotor winding can enable increased torque production, especially during starting and low-speed operation, leading to improved

overall motor performance.

4. Modified Wound Rotor Design:

Rotor Construction: Employing a modified wound rotor design with different slot configurations or conductor materials can optimize the motor for higher torque output without sacrificing efficiency.

5. Variable Frequency Drives (VFDs):

Speed Control: Implementing a VFD allows for precise control over the motor's speed and torque, enabling the motor to operate efficiently at varying load conditions while providing

higher torque when needed.

6. Soft Starters:

Reduced Starting Current: Soft starters can be employed to reduce the initial inrush current, minimizing voltage drops and improving torque during motor startup without compromising

the electrical system.

7. Specialized Control Algorithms:

Advanced Motor Control: Utilizing specialized control algorithms such as field-oriented control (FOC) or vector control can optimize torque production and overall motor performance under

varying load conditions.

8. Thermal Management:

Cooling Systems: Enhancing the motor's cooling systems can help manage temperature rise during higher torque operations, ensuring that the motor operates within safe thermal limits while

delivering improved torque output.

9. Consultation with Experts:

Professional Evaluation: Engaging with motor experts and consultants can provide valuable insights into specific motor modifications and optimizations tailored to the unique requirements of the

application and the motor itself.

By implementing these strategies, it is possible to enhance the torque output of a slip ring induction motor, thereby expanding its capability to handle higher loads and more demanding operating

conditions, ultimately improving its effectiveness across various industrial and commercial applications.

For more details on electric conductive slip ring products, please view :https://www.senring.com/rotary-unions/electrical-pneumatic/

FAQ questions:

1.How do I choose a Industrial Bus slip ring?

2.What is the current rating of a slip ring?

3.What is difference between slip ring and split ring?

4.What is the function of through-hole conductive slip rings?

5.What is capsule slip ring and is used for?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE