What is the difference between a rotary joint and a rotary union?

A rotary joint is a type of mechanical device that allows for the transfer of energy or motion between two shafts that are not aligned. It typically consists of a seriesof gears, pulleys, or other mechanisms that allow for the rotation of one shaft to be transferred to another shaft at a different angle or orientation.

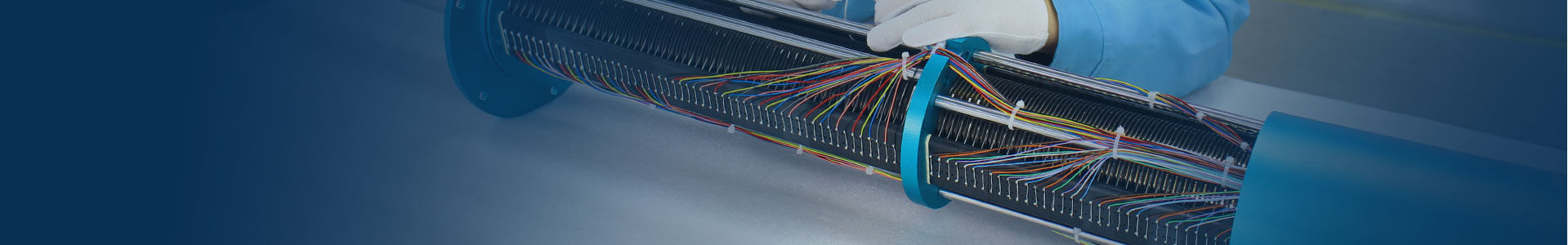

A Pneumatic Rotary Union, on the other hand, is a type of coupling device that allows for the transfer of fluids or gases between two rotating components. It typically consists of

a series of seals and bearings that allow for the rotation of one component while maintaining a leak-free connection between the two components.

In summary, a rotary joint is used for transferring motion between two shafts, while a rotary union is used for transferring fluids or gases between two rotating components.

The lifespan of direct drive motors can vary significantly based on several factors, including operational conditions, maintenance practices, environmental factors, and the

specific design and construction of the motor itself. While it's challenging to provide an exact lifespan for all direct drive motors, here are some key considerations

that influence their longevity:

Operational Conditions:

Duty Cycle: The frequency and duration of motor operation impact its lifespan. Continuous or high-duty cycle operations may lead to more rapid wear compared to intermittent use.

Load Characteristics: Motors subjected to heavy loads or frequent start-stop cycles may experience higher mechanical stress, potentially affecting their service life.

Environmental Factors: Exposure to extreme temperatures, dust, humidity, or corrosive substances can influence the longevity of a motor. Proper environmental protection and

suitable operating conditions can extend its lifespan.

Maintenance Practices:

Regular Inspections: Scheduled inspections and preventive maintenance measures can help identify potential issues early, allowing for timely repairs or adjustments to prolong motor life.

Lubrication: For motors requiring lubrication, adherence to proper lubrication schedules and practices is crucial for minimizing wear and ensuring smooth operation.

Alignment and Balancing: Correct alignment and balancing of motor components, particularly in high-speed applications, can prevent premature wear and extend motor life.

Design and Construction:

Quality of Components: The quality of materials used, precision of manufacturing, and the robustness of the motor's construction can influence its durability and expected lifespan.

Overload Protection: Motors equipped with effective overload protection mechanisms are less susceptible to damage from excessive current or torque, potentially extending

their operational life.

Application-Specific Considerations:

Industrial vs. Residential Use: Direct drive motors employed in industrial settings may be subject to harsher conditions and heavier loads compared to those used in residential

appliances, impacting their respective lifespans differently.

Maintenance Practices: Adherence to recommended maintenance procedures, as well as prompt resolution of any identified issues, plays a critical role in ensuring the long-term

performance and reliability of direct drive motors across various applications.

Given these factors, the service life of direct drive motors can range from several years to multiple decades, with some motors lasting 20 years or more when operated within their design

parameters and properly maintained. However, it's essential to consider the specific context of motor usage and the aforementioned influencing factors to accurately assess and optimize

the lifespan of any given direct drive motor.

For more details on slip ring products, please view :https://www.senring.com/rotary-unions/electrical-pneumatic/

FAQ questions:

1.What would be the effect of using a slip ring instead of a split ring commutator?

2.Are thorugh hole slip rings usually made of copper?

3.What is the difference between a slip ring and a commutator ring?

4.Does wound rotor motor need slip ring and brushes?

5.What is capsule slip ring and is used for?

- What is the function of Pneumatic Rotary Union & joints actuators?

-

- 09-01-2024

- Pneumatic Rotary Union actuators are used in a variety of applications, including industrial automation, robotics, and medical devices.They are typically used to c

- more+

- How can Pneumatic Rotary Union & Rotary Joint solve rotation transmission problems?

-

- 05-12-2023

- Pneumatic Rotary Union & Rotary Joint is an electrical component responsible for connecting and transmitting current and signals from rotating objects. It can c

- more+

- How to wire a Pneumatic Rotary Union & Rotary Joint?

-

- 13-11-2023

- The gas-electric slip ring, also known as the Pneumatic Rotary Union & Rotary Joint, is a conductive ventilation and conductive device that can rotate 360°

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE