What would be the effect of using a slip ring instead of a split ring commutator?

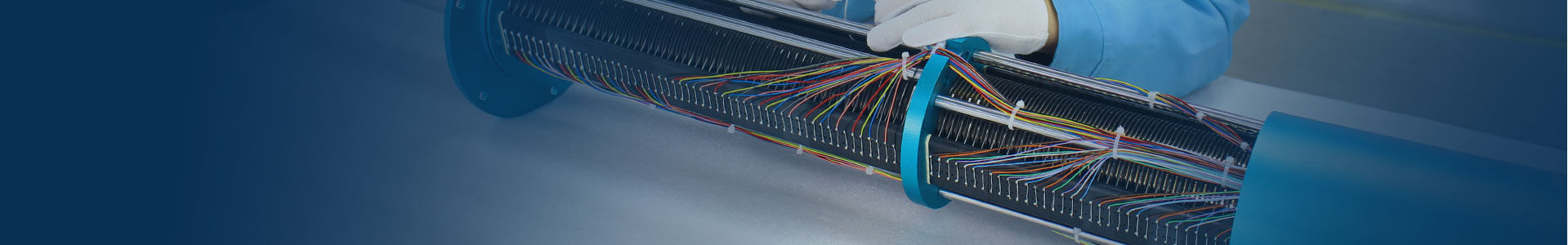

A slip ring is a type of commutator used in some types of electric motors and generators. It differs from a split ring commutator in its construction and the way it interacts with the magnetic field of the machine.A slip ring commutator consists of a number of metal rings that are insulated from each other but can slide past one another. Each ring is connected to a different armature coil.

As the armature rotates, the electrical capsule slip ring slide over a set of brushes that collect the current generated by the coils or supply current to them.

In contrast, a split ring commutator has a single ring that is split into segments, each connected to a different armature coil. The brushes ride on the surface of the commutator,

making contact with the various segments as they pass under the brushes.

The effect of using a slip ring instead of a split ring commutator would be:

Smoother Operation: Slip rings provide a smoother operation because there are multiple points of contact between the brushes and the commutator, reducing sparking and wear.

Higher Efficiency: The continuous contact between the brushes and the slip rings can result in higher efficiency compared to a split ring commutator where contact is interrupted as

the brushes move from one segment to another.

Longer Life: The sliding action of capsule slip ring brushes against the brushes can distribute wear more evenly, potentially extending the life of the commutator and brushes compared

to a split ring design.

Increased Complexity: Slip ring commutators are typically more complex in design and may require more precision in manufacturing and assembly than split ring commutators.

1. Commutation Method:

Split Ring Commutator: In a traditional DC motor, the split ring commutator is responsible for reversing the current flow in the rotor windings, ensuring continuous rotation through the

reversal of magnetic field polarity.

Slip Ring: Using a slip ring instead of a split ring commutator would typically indicate a shift from a DC motor to an AC motor or a different type of rotating electrical machine.

2. Motor Type:

DC Motor with Split Ring Commutator: A motor using a split ring commutator is typically a direct current (DC) motor, where the commutator facilitates the conversion of alternating current

in the armature winding to direct current in the rotor windings, ensuring continuous rotation.

Slip Ring Application: Slip rings are commonly used in AC motors, generators, and certain types of wound rotor induction motors, providing a means for transferring electrical power and control

signals to a rotating component without the need for continuous reversal of current.

3. Electrical Connections:

Split Ring Commutator: Directly controls the current flow in the rotor windings, facilitating the generation of a continuous torque in a DC motor by periodically reversing the direction of current

flow as the rotor rotates.

Slip Ring: Facilitates the transmission of electrical power, control signals, or other electrical functions to a rotating component, such as the rotor of an AC motor or a wound rotor induction motor.

4. Operational Characteristics:

Continuous vs. Reversible Rotation: The use of a split ring commutator enables continuous rotation in one direction in a traditional DC motor. In contrast, a slip ring allows bidirectional flow of power

and control signals, enabling features such as variable speed operation and reversible rotation in AC motors or wound rotor induction motors.

5. Mechanical Design:

Rotor Construction: In a DC motor utilizing a split ring commutator, the rotor incorporates windings connected to the commutator segments. Conversely, if a slip ring is employed, the rotor construction

and winding configuration would align with the operational requirements of AC or wound rotor induction motor designs.

In summary, using a slip ring instead of a split ring commutator would generally result in smoother operation, higher efficiency, and potentially longer life at the expense of increased complexity

and possibly different applications.

For more details on slip ring products, please view :https://www.senring.com/capsule-slip-ring/

FAQ questions:

1.How do you control the speed of a slip ring motor?

2.What are the limitations of Pancake Slip Rings?

3.What is the difference between a slip ring and a commutator ring?

4.What are the purpose of slp ings on rotor?

5.What is capsule slip ring and is used for?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE