What is the difference between a slip ring and a commutator ring?

A slip ring is a circular metal ring that is mounted on the rotating shaft of an electrical machine. It has a set of brushes that make contact with the ring as it rotates,allowing electrical current to flow through the brushes and into the rotating part of the machine. Slip rings are commonly used in applications such as generators,motors, and transformers.

On the other hand, a commutator ring is a type of Through Hole Slip Ring that is designed specifically for use in DC motors and generators. It consists of a number

of segments that are insulated from each other and connected to different parts of the machine's armature. As the armature rotates, the brushes make contact with

different segments of the commutator ring, causing the current to reverse direction and allowing the machine to produce a continuous output.

In summary, while both slip rings and commutator rings are used to transfer power from one rotating part to another, the main difference between them is that

commutator rings are designed specifically for use in DC motors and generators, while slip rings can be used in a wider range of electrical machines.

The terms "slip ring" and "commutator ring" are both related to electrical connections in rotating systems, specifically in the context of electric motors. While they share

similarities in their function as components for transferring electrical signals or power between stationary and rotating parts, there are fundamental differences in their

designs, applications, and roles within various motor types. Here's a breakdown of the differences between slip rings and commutator rings:

Slip Ring:

Function: A slip ring is an electromechanical device that enables the transmission of electrical power and signals from a stationary to a rotating structure. It allows the

transfer of power, data, or control signals to rotating components such as rotors, shafts, or other moving parts without the risk of wires tangling or breaking due to rotation.

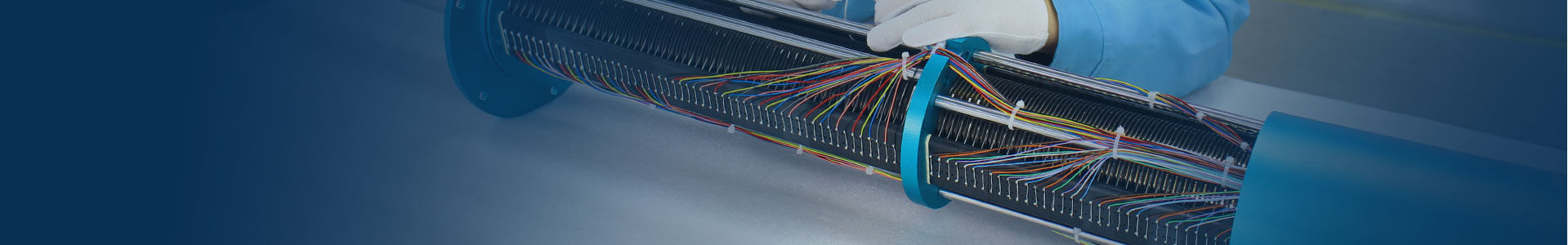

Design: Slip rings consist of conductive rings mounted on the rotating part of a system, with stationary brushes or contacts making contact with these rings. This arrangement

allows for continuous electrical connectivity as the rings rotate, providing a reliable means of transmitting power or signals.

Applications: Slip rings are commonly used in various rotating machinery and equipment, including wind turbines, industrial machinery, electrical generators, radar systems, and

other applications requiring consistent electrical connections across rotational interfaces.

Commutator Ring:

Function: A commutator ring is a specific type of split-ring component used in DC (direct current) motors to switch the direction of the current in the motor's windings, ensuring

continuous rotation. It serves to reverse the polarity of the electromagnets in the motor, enabling the production of a continuous torque for rotational motion.

Design: In DC motors, the commutator ring is typically mounted on the motor's rotor and consists of multiple segments connected to the armature coils. As the rotor spins, the

commutator reverses the direction of current flow in the winding coils, allowing the motor to maintain a consistent rotational direction.

Applications: Commutator rings are exclusively found in DC electric motors and generators, providing a mechanism to ensure the continuous rotation and proper functioning of

these devices by facilitating the reversal of current in the rotor windings.

Main Differences:

Function: electric slip rings primarily enable the transmission of power and signals across rotating interfaces, while commutator rings serve the specific function of reversing current

direction in DC motor windings to facilitate continuous rotation.

Design and Application: Slip rings are utilized in a wide range of rotating systems and machinery, whereas commutator rings are specific to DC electric motors and generators.

In summary, while both slip rings and commutator rings play crucial roles in facilitating electrical connections within rotating systems, their distinct designs, functions, and

applications set them apart, with slip rings serving as general-purpose rotating electrical connectors and commutator rings being specialized components essential for the

operation of DC motors and generators.

For more details on slip ring products, please view :https://www.senring.com/industrial-bus/bh38119.html

FAQ questions:

1.Why do we use carbon brushes in high speed slip ring motor?

2.Do through hole slip rings rotate with the coil?

3.How do I choose a Industrial Bus slip ring?

4.What are the purpose of slp ings on rotor?

5.What is capsule slip ring and is used for?

- Is through hole slip ring same as magic ring in crochet?

-

- 15-04-2024

- No, through hole slip ring and magic ring in crochet are not the same. A through hole slip ring is a type of bead that can be used to make jewelry. A magic ring

- more+

- What metal is used in through hole slip rings?

-

- 26-02-2024

- Copper is the most common metal used in through hole slip rings.Through hole slip rings, which are used for the transmission of electrical signals and power acr

- more+

- Do through hole slip rings rotate with the coil?

-

- 12-01-2024

- No, slip rings do not rotate with the coil. through hole Slip rings are stationary and are used to transfer electrical current between two separate parts of a m

- more+

- Why were through hole slip rings so important to helical scanning?

-

- 09-04-2024

- Slip rings were important to helical scanning because they allowed the rotation of the electron beam in the CRT (cathode ray tube) to be synchronized with the r

- more+

- What is the difference between through hole Slip Ring and carbon brushes?

-

- 13-03-2024

- Through-hole slip rings and carbon brushes are both components used in electrical systems, particularly in rotating machinery, to transfer electrical signals or

- more+

- Why do we use through hole slip ring induction motor?

-

- 02-04-2024

- Through-hole slip ring induction motors are used in specific applications where continuous rotation of a component or device is required while maintaining elect

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE