What is the difference between through hole Slip Ring and carbon brushes?

Through-hole slip rings and carbon brushes are both components used in electrical systems, particularly in rotating machinery, to transfer electrical signals or power between stationary and rotating parts. However, they operate on different principles and have distinct characteristics:Through-Hole Slip Ring:

A through-hole slip ring is a rotary electrical joint that allows the transmission of electrical signals or power from a stationary part to a rotating part.

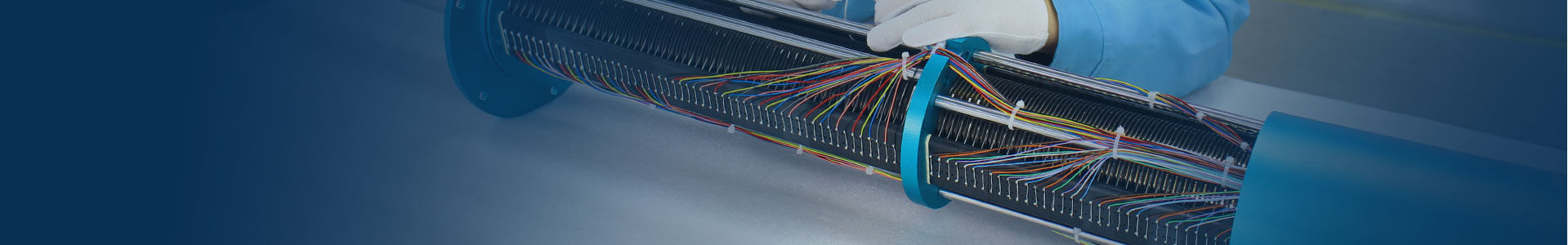

It consists of a stationary part (stator) and a rotating part (rotor) separated by an insulating material. The rotor typically has conductive rings mounted on it, while the stator has brushes or contacts that make contact with the rings.

As the rotor rotates, the brushes maintain contact with the rings, enabling the transfer of electrical signals or power without the need for physical wires that would twist or tangle during rotation.

Through-hole slip rings are commonly used in applications where continuous rotation is required, such as in rotary joints for radar systems, wind turbines, robotics, and industrial machinery.

Carbon Brushes:

Carbon brushes are electrical contacts that slide against a rotating or moving surface to provide an electrical connection.

They are typically made of carbon or graphite, which have good electrical conductivity and wear resistance properties.

Carbon brushes are used in various applications, including electric motors, generators, alternators, and some slip ring configurations.

Unlike slip rings, carbon brushes are used to transfer power or signals in applications where continuous rotation is not required, or where the rotational speed is relatively low.

Design:

Through-hole slip rings are circular or cylindrical components with a central hole that allows them to be mounted on a shaft. They have a series of electrical contacts (called fingers) that extend from the outer edge of the ring to the center, where they connect to the stationary circuit.

Carbon brushes are typically rectangular or cylindrical in shape and are mounted in brush holders that allow them to make contact with the slip ring. They are usually spring-loaded to ensure consistent pressure against the slip ring.

Function:

Through-hole slip rings are part of the rotating assembly and rotate with the shaft. They provide a continuous electrical connection between the rotating and stationary parts of the system.

Carbon brushes are part of the stationary assembly and slide on the surface of the slip ring as it rotates. They transmit the electrical current to or from the rotating part of the system.

In summary, through-hole slip rings are the rotating components that provide electrical continuity, while carbon brushes are the sliding components that transmit the current between the slip ring and the stationary circuit. Both components work together to enable electrical communication between rotating and non-rotating parts of a system.

For more details on through hole Slip Ring products, please view :https://www.senring.com/through-hole-slip-ring/medium-hole/h60130.html

FAQ questions:

1.What does the high current slip rings do on a steering wheel?

2.What are the two functions of industrial bus slip sings and brushes?

3.How does a Deublin rotary union pneumatic work?

4.What metal is used in through hole slip rings?

5.Are thorugh hole slip rings usually made of copper?

- Do miniature through hole slip rings rotate with the coil?

-

- 26-03-2024

- Yes, slip rings rotate with the coil. The purpose of a slip ring is to allow a rotating coil to communicate with a fixed circuit. A slip ring is a mechanical de

- more+

- Why were through hole slip rings so important to helical scanning?

-

- 09-04-2024

- Slip rings were important to helical scanning because they allowed the rotation of the electron beam in the CRT (cathode ray tube) to be synchronized with the r

- more+

- Is through hole slip ring same as magic ring in crochet?

-

- 15-04-2024

- No, through hole slip ring and magic ring in crochet are not the same. A through hole slip ring is a type of bead that can be used to make jewelry. A magic ring

- more+

- Do through hole slip rings rotate with the coil?

-

- 12-01-2024

- No, slip rings do not rotate with the coil. through hole Slip rings are stationary and are used to transfer electrical current between two separate parts of a m

- more+

- Why do we use through hole slip ring induction motor?

-

- 02-04-2024

- Through-hole slip ring induction motors are used in specific applications where continuous rotation of a component or device is required while maintaining elect

- more+

- What is the difference between through hole Slip Ring and carbon brushes?

-

- 13-03-2024

- Through-hole slip rings and carbon brushes are both components used in electrical systems, particularly in rotating machinery, to transfer electrical signals or

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE