Are Industrial Bus slip rings usually made of copper?

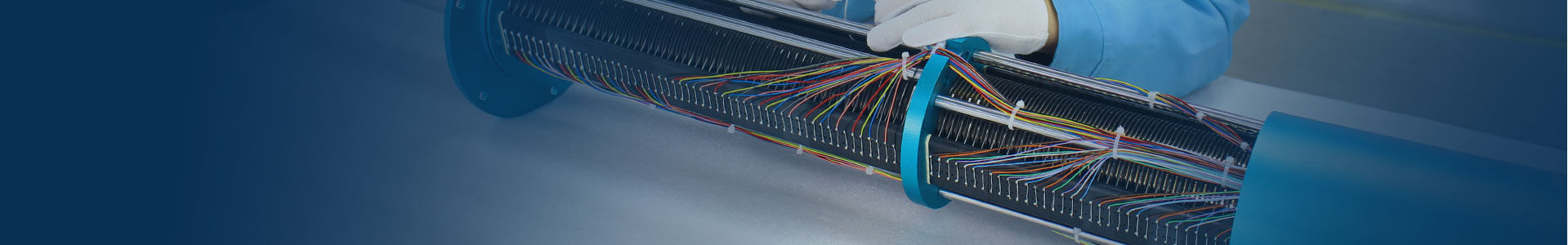

Yes, Industrial Bus slip rings are usually made of copper.Industrial Bus slip rings are not typically made entirely of copper. Instead, they often feature copper-based components within their construction to facilitate the reliable

transmission of electrical signals and power across rotating interfaces. These slip rings utilize various materials to ensure efficient electrical connectivity while withstanding

the mechanical and environmental demands of industrial applications. Here's how copper is commonly utilized within Industrial Bus slip rings:

Conductive Rings: Typically, the conductive slip rings within slip rings are made of high-quality, high-conductivity materials such as copper alloys. Copper's excellent electrical

conductivity makes it an ideal choice for transmitting signals and power across the rotating interface.

Brush Contacts: Many slip rings use carbon brushes or precious metal brushes (such as silver or gold) in contact with the conductive rings. These brushes make electrical contact

with the rings and transfer current or signals from the stationary part to the rotating part. While copper itself is not used as a brush material due to its relatively low wear resistance,

it forms a part of the overall electrical pathway.

Plating: In some cases, the surfaces of the conductive rings may be plated with materials like silver or gold to improve their wear resistance, reduce friction, and enhance their ability

to maintain consistent electrical contact with the brush contacts. While copper itself isn't typically used as the primary plating material, it serves as a base layer for these coatings.

Support Structures: Copper may also be used in other components within the torque drive motor assembly, such as support structures, connectors, or wiring, where its excellent

electrical conductivity and mechanical properties can be advantageous.

In summary, while copper is not the exclusive material used in the construction of Industrial Bus slip rings, it plays a crucial role in the electrical pathways, conductive rings, and

support structures within the slip ring assembly. The use of copper-based components ensures efficient electrical transmission and helps maintain reliable connectivity in

demanding industrial environments.

For more details on slip ring products, please view :https://www.senring.com/industrial-bus/bh38119.html

FAQ questions:

1.How do Fibre optic slip rings work?

2.Do through hole slip rings rotate with the coil?

3.What are the purpose of slp ings on rotor?

4.What are the purpose of slp ings on rotor?

5.What is capsule slip ring and is used for?

- Are Industrial Bus slip rings usually made of copper?

-

- 24-01-2024

- Yes, Industrial Bus slip rings are usually made of copper. Industrial Bus slip rings are not typically made entirely of copper. Instead, they often feature cop

- more+

- What material are Industrial Bus Slip Rings made of?

-

- 22-02-2024

- Industrial Bus Slip Rings are typically made of copper or aluminum, as these materials provide excellent electrical conductivity and durability. However, the sp

- more+

- What are the application fields of industrial bus slip rings?

-

- 11-12-2023

- The industrial bus slip ring is an electrical component responsible for connecting and transmitting energy and signals to rotating bodies. According to the tran

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE