How does a fiber optic rotary joint work?

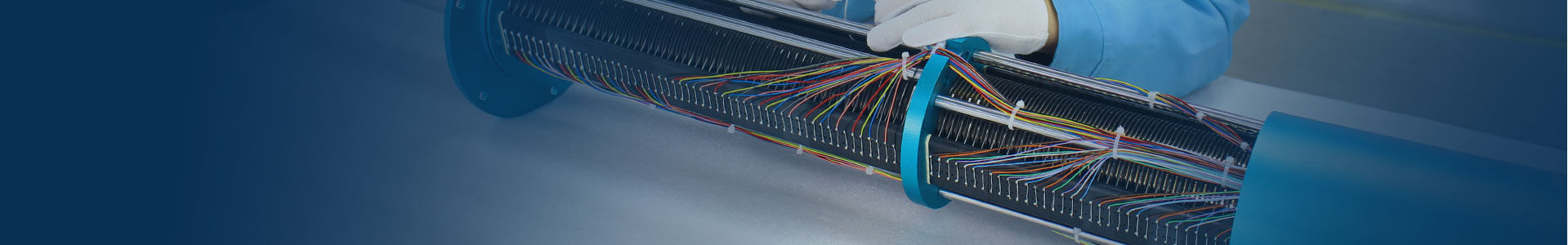

A fiber optic rotary joint, also known as a fiber optic slip ring or rotary coupler, is a device that allows the transmission of light signals through an optical fiber while allowing rotation between two connected parts. It is commonly used in applications such as robotics, industrial automation, and communication systems where there is a need to transmit data or power through a rotating connection.The basic components of a fiber optic rotary joint include a stator (the stationary part) and a rotor (the rotating part). The stator contains the input and output fibers, while the rotor has a set of lenses or mirrors that redirect the light signal from the input fiber to the output fiber.

As the rotor rotates, the lenses or mirrors move with it, maintaining the optical path between the input and output fibers. This ensures that the light signal is transmitted continuously, even as the rotor moves.

A fiber optic rotary joint (FORJ) facilitates the transmission of optical signals across a rotating interface. It is commonly used in applications such as fiber optic communication systems, undersea cabling, medical devices, and various sensors. The function of a fiber optic rotary joint involves ensuring continuous and uninterrupted transmission of optical signals between stationary and rotating components. Here's how it works:

Optical Signal Transmission:

In a fiber optic rotary joint, optical fibers from the stationary component are aligned with corresponding fibers on the rotating side to establish a continuous path for transmitting optical signals.

Rotational Interface:

The FORJ features a carefully engineered rotational interface that allows the optical fibers to rotate without twisting or breaking. This interface maintains precise alignment between the fibers to minimize signal loss and maintain signal integrity.

Lenses and Collimators:

Many fiber optic rotary joints incorporate lenses and collimators to couple the light between the stationary and rotating fibers. These optical components help to ensure that the transmitted signals remain focused and efficiently transferred despite the rotational movement.

Multi-Channel Transmission:

Advanced fiber optic rotary joints can support multiple optical channels, allowing for the simultaneous transmission of several independent optical signals across the rotating interface.

Minimal Signal Loss:

The design of the FORJ aims to minimize signal loss, insertion loss, and crosstalk during rotation. Precision engineering and high-quality materials are employed to achieve low attenuation and maintain high signal quality.

Environmental Protection:

Fiber optic rotary joints are often sealed and protected against environmental factors such as moisture, dust, and temperature variations to ensure long-term reliability and performance.

Overall, a fiber optic rotary joint works by providing a reliable and continuous pathway for transmitting optical signals across a rotating interface, enabling seamless communication in systems where rotational movement is present while maintaining the integrity of the transmitted optical signals.

For more details on fiber optic rotary joint products, please view :https://www.senring.com/fiber-optic-rotary-joints/4-channel-forj/fo408.html

FAQ questions:

1.How do you know if a through bore slip ring is bad?

2.Why do we use through hole slip ring induction motor?

3.Do miniature through hole slip rings rotate with the coil?

4.What is the current rating of a high current slip ring?

5.Are thorugh hole slip rings usually made of copper?

- How does a fiber optic rotary joint work?

-

- 10-04-2024

- A fiber optic rotary joint, also known as a fiber optic slip ring or rotary coupler, is a device that allows the transmission of light signals through an optica

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE