What is the service life and reliability of high-speed slip rings?

The service life and reliability of high-speed slip rings are their key performance indicators, especially in application environments such as aerospace and aviation. , due to the need to face high-speed and high-temperature operating conditions, they must have excellent signal transmission quality and safety and reliability.1. The following are several main factors that affect the service life and reliability of high-speed slip rings:

Material selection: In order to resist the strong friction and wear caused by high-speed rotation, high-speed slip rings need to use high-strength and high-wear-resistant materials.

Speed and life: For example, the life of the LPC-0210 high-speed conductive slip ring can reach more than 100 million revolutions. But it is worth noting that the higher the slip ring's rotational speed does not necessarily mean that its performance is better.

Brush pressure stability: Reasonable brush pressure can ensure the maximum service life of the conductive slip ring.

Technical indicators: The main technical indicators of conductive slip rings also include insulation performance, anti-interference performance and contact resistance.

In order to ensure the long life and reliability of high-speed slip rings, in addition to the above factors, regular maintenance and inspections are also required to ensure that they can work stably in various environments.

2. The service life and reliability of high-speed slip rings depend on many factors, including but not limited to the following:

Operating conditions: High-speed slip rings operate under specific operating conditions, including rotational speed, load, temperature and environmental factors. These factors will directly affect its service life and reliability.

Materials and Manufacturing Quality: The material selection and manufacturing process of a high-speed slip ring are critical to its longevity and reliability. High-quality materials and precision processing can improve its wear resistance and stability.

Lubrication and Maintenance: Proper lubrication and regular maintenance are key to ensuring long-term reliable operation of high-speed slip rings. Lack of proper lubrication and maintenance may reduce its lifespan.

Design and structure: Whether the design of the high-speed slip ring is reasonable, whether factors such as vibration and impact are considered, and effective measures are taken to reduce these effects on the slip ring.

Load type: Different types of loads have different effects on high-speed slip rings, such as radial load, axial load, torque, etc., which will have an impact on life and reliability.

Environmental factors: The environmental conditions in which high-speed slip rings are located, including temperature, humidity, corrosive gases, etc., will affect their life and reliability.

In order to ensure the service life and reliability of high-speed slip rings, users should carry out correct installation, operation and maintenance according to the manufacturer's recommendations, while conducting regular inspections as needed and dealing with discovered problems in a timely manner.

FAQ question:

1.How to install through-hole conductive slip ring?

2.What are the application fields of industrial bus slip rings?

3.What is the principle of high current conductive slip ring?

4.How does a slip ring motor transform its voltage?

5.Application of slip ring in public facilities

- How to solve the temperature and signal transmission problems caused by high-speed slip rings?

-

- 04-12-2023

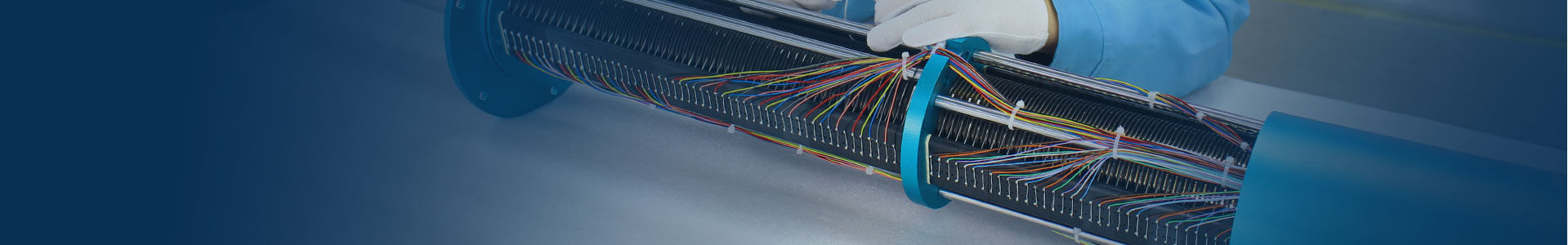

- A high-speed slip ring is a device that maintains a continuous electrical connection during rotational motion and is used to transmit power, signals, and data.

- more+

- What is the service life and reliability of high-speed slip rings?

-

- 15-12-2023

- The service life and reliability of high-speed slip rings are their key performance indicators, especially in application environments such as aerospace and avi

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE