How to solve the temperature and signal transmission problems caused by high-speed slip rings?

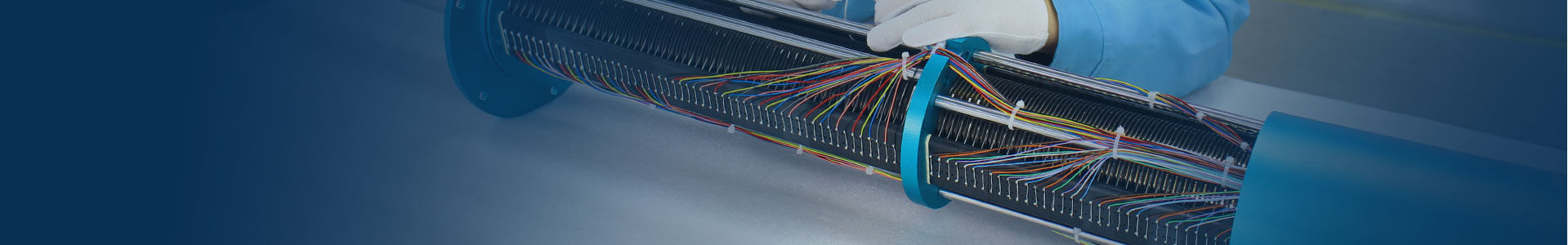

A high-speed slip ring is a device that maintains a continuous electrical connection during rotational motion and is used to transmit power, signals, and data. It ensures that rotating parts can operate smoothly and transmit various signals and data when needed, especially in high-speed precision equipment.1. In order to solve the temperature and signal transmission problems caused by high-speed slip rings, the following solutions are widely used:

Friction pair design: By adopting the design of high-speed slip ring single ring double brush parallel sliding friction pair, the reliability of signal transmission can be improved.

Material and design optimization: Using advanced materials and innovative design methods, the thermal conductivity of the slip ring can be enhanced to dissipate heat more effectively and ensure that it can still work reliably in high temperature environments.

Electromagnetic interference suppression: Using precious metal contact transmission method inside the slip ring and performing corresponding shielding treatment can effectively reduce the impact of external electromagnetic on the slip ring, thereby improving the signal transmission quality.

Innovation in signal transmission technology: Combining the latest signal transmission technology, such as optical fiber technology or wireless communication technology, can achieve higher data transmission rates and longer transmission distances.

2. It is necessary to comprehensively consider various factors such as mechanical design, material selection, and signal transmission technology. Here are some workarounds:

Optimized heat dissipation design: For electric slip rings, optimized heat dissipation design can effectively control temperature problems. Using appropriate heat dissipation materials, increasing the heat dissipation surface area, and designing heat dissipation structures can help reduce the temperature of high-speed slip rings.

Lubrication and cooling system: Using lubricants or setting up a cooling system in high-speed slip rings can effectively reduce the heat generated by friction, thereby controlling the temperature and extending the service life of the slip ring.

Choose appropriate materials: Use high-temperature-resistant and corrosion-resistant materials to make high-speed slip rings, such as stainless steel, special alloys, etc., to improve their ability to withstand high-temperature environments.

Adopt digital signal transmission technology: The use of digital signal transmission technology can effectively eliminate interference and attenuation during signal transmission and improve signal stability and reliability.

Use optical fiber transmission technology: If the environmental conditions are complex, you can consider using optical fiber transmission technology to solve the signal transmission problem. Optical fiber has the advantages of anti-interference and long transmission distance.

Adopting contactless transmission technology: Through contactless transmission methods, such as electromagnetic induction coupling, capacitive coupling, etc., the wear and signal attenuation problems that may occur in traditional contact transmission are avoided.

In summary, through the combination of the above methods and technologies, the temperature and signal transmission problems that high-speed slip rings may encounter in practical applications can be effectively solved.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE