How to install through-hole conductive slip ring?

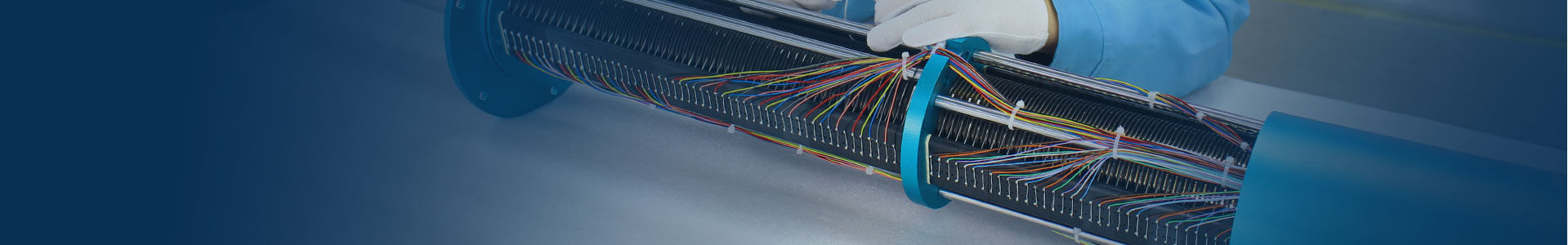

A through-hole conductive slip ring, also known as a hollow shaft slip ring, is a rotating conductive device with a central hole. This kind of slip ring is mainly used on equipment with a rotating shaft. Insert the shaft of the rotating device into the center hole of the slip ring, and then fix the anti-rotation plate of the slip ring.1. The installation of through-hole conductive slip rings usually requires the following steps:

Preparation: Before installation, be sure to clean the installation location and inspect all parts to ensure integrity. At the same time, it is necessary to understand and confirm the correct installation direction and position of the conductive slip ring.

Fixed base: Fix the base (usually disc-shaped) of the conductive slip ring in a suitable position on the mechanical equipment, ensuring that it is stable and aligned with the rotating parts.

Connecting Leads: If a conductive slip ring requires connecting wires or leads, be sure to connect them to the appropriate terminals and allow sufficient length to accommodate rotational movement.

Cooperate with the mechanical structure: According to the actual situation, adjust the position of the conductive slip ring and its cooperation with other mechanical structures to ensure that it can rotate freely without any external interference.

Testing and debugging: After completing the installation, carry out necessary testing and debugging to ensure that the conductive slip ring rotates freely and has good transmission performance, while eliminating possible problems.

Lubrication and Protection: Lubrication and protection may be required for certain models of conductive slip rings to ensure long-lasting performance and reliability during use.

2. Please pay attention to the following points during the installation process:

Slip rings should be protected from dust and moisture. If used outdoors, a protective cover should be installed.

Protect the surface of all wires from damage when the device rotates. Pay special attention to ensuring that all wire ends cannot bear weight when arranging wires.

Slip rings are precision electrical components and should work in a dry and dust-free environment. If the environment is harsh, protective measures should be added.

Since it is difficult to ensure that the slip ring rotor and stator are concentric during installation, it is recommended to use 4 set screws to fix the miniature through hole slip ring on the rotating shaft. Before tightening the screws, please turn the rotary electrical slip rings first and let the conductive ring automatically find the center of the positive rotating shaft, and then tighten the screws.

Just insert the anti-rotation rod into the anti-rotation plate, but remember not to forcibly fix the anti-rotation plate, otherwise it may cause damage or shorten the expected service life.

Special care should be taken during the installation process to ensure that the internal parts of the conductive slip ring are not damaged so that it can work stably and reliably. If you are not sure how to install it, it is recommended to consult professionals in the relevant field or refer to the installation manual.

FAQ question:

1.What are the application fields of industrial bus slip rings?

2.What is the principle of high current conductive slip ring?

3.What are the contact methods for rotating conductive slip rings?

4.How to fix and install pneumatic rotary joints?

5.When selecting a high-speed slip ring,what factors do you need to consider?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE