How to fix and install pneumatic rotary joints?

1.How to fix and install pneumatic rotary jointsPneumatic rotary joint is a connection sealing device used to input fluid media from a stationary pipe to a rotating or reciprocating device. To secure a pneumatic swivel joint, follow these steps:

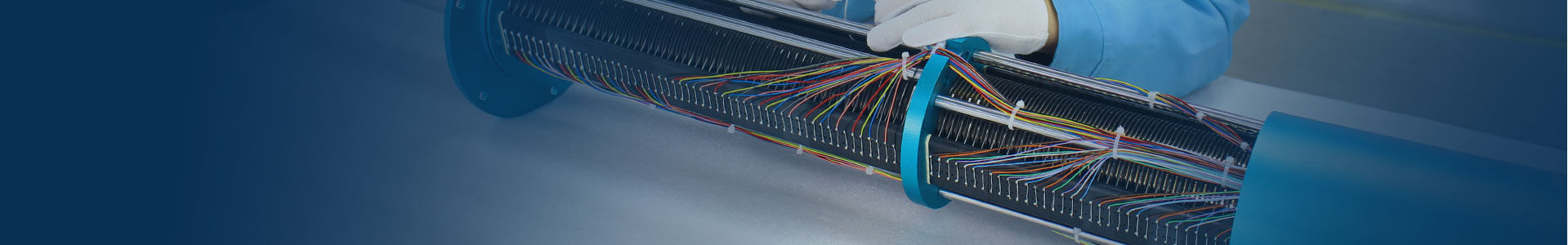

The rotor part of the rotary union for air usually has 4 fixing holes, some of which are U-shaped. Secure these holes to the device's axis of rotation.

Pass the air outlet hole of the rotor through the center hole of the rotating shaft.

Secure the rotor end of the air slip ring (blue part). There are usually multiple fixing holes in this part, and customers can choose which holes to use for fixing according to the actual situation.

After installation, use your hands to push the displacement evenly along the axial direction from the tail of the rotary joint to ensure that the joint has room for automatic adjustment of seal wear. Th

After installation, use your hands to push the displacement evenly along the axial direction from the tail of the rotary joint to ensure that the joint has room for automatic adjustment of seal wear. This step is to ensure that the rotary joint can work normally. It is not fixed with metal hose or anti-rotation and has a compensation effect.

In addition, the inner tube of some rotary joints is installed on the connecting shaft of the rotary joint, and the other end is inserted inside the equipment. In this way, the inner tube will rotate synchronously with the equipment and be fixed with threads on the rotating joint.

1.How to fix and install pneumatic rotary joints

Pneumatic rotary joint is a connection sealing device used to input fluid media from a stationary pipe to a rotating or reciprocating device. To secure a pneumatic swivel joint, follow these steps:

The rotor part of the pneumatic rotary joint usually has 4 fixing holes, some of which are U-shaped. Secure these holes to the device's axis of rotation.

Pass the air outlet hole of the rotor through the center hole of the rotating shaft.

Secure the rotor end of the air slip ring (blue part). There are usually multiple fixing holes in this part, and customers can choose which holes to use for fixing according to the actual situation.

After installation, use your hands to push the displacement evenly along the axial direction from the tail of the rotary joint to ensure that the joint has room for automatic adjustment of seal wear. This step is to ensure that the rotary joint can work normally. It is not fixed with metal hose or anti-rotation and has a compensation effect.

2.When installing a pneumatic swivel joint, follow these steps:

1. Clean the work area: Before starting the installation, make sure the work area is clean and remove any debris or dirt that may affect the installation.

2. Check the pneumatic rotary joint: Make sure there are no damaged or loose parts in the pneumatic rotary joint itself. Check whether its connecting parts and seals are intact.

3. Prepare the installation location: Determine the installation location of the pneumatic rotary joint and clean the location to ensure that the surface is flat and free of obstacles.

4. Connect the air inlet pipe: Connect the air source pipe to the air inlet interface of the pneumatic rotary joint, making sure to tighten it and use appropriate seals.

5. Ground connection: If grounding is required, make sure a suitable ground wire or clamp is connected.

6. Fixtures: Securely mount the pneumatic swivel joint to the equipment using bolts, clamps, or other appropriate fixation devices in accordance with the guidelines provided by the manufacturer.

7. Connect the output line: Connect the output line of the pneumatic rotary joint, making sure the connection is tight and using appropriate seals.

8. Test operation: After installation is completed, conduct a brief test to ensure that the pneumatic rotary joint is installed correctly and working properly.

9. Adjust the position: If necessary, adjust the position of the pneumatic rotary joint according to specific needs to ensure that it cooperates well with other systems or equipment.

When installing a pneumatic swivel joint, the most important thing is to carefully follow the installation guidelines provided by the manufacturer and ensure that all connections and fixings are properly handled to ensure safety and reliability.

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE