What are the contact methods for rotating conductive slip rings?

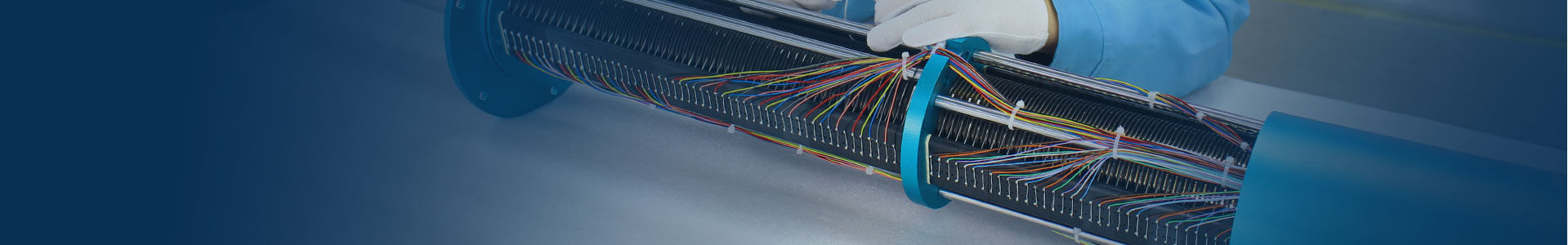

The contact mode of the rotating conductive slip ring is mainly achieved through sliding contact. The interior of the conductive slip ring is made of conductive materials such as brush-plated silver, gold or carbon brushes. These conductive materials have good conductive properties. When the rotating part begins to rotate, friction is generated at the contact surface between the conductive materials, forming a closed circuit. Electrical energy and signals can be transmitted to the rotating parts through this circuit to achieve electrical connection.In addition, the connection method of the rotating conductive slip ring is closely related to its outer dimensions and structure, and is generally divided into several types such as through-hole type, flange type, and split type.

There are differences in the wiring methods of different types of slip rings. For example, the wiring method of a through-hole slip ring is from both ends of the slip ring and the end face of the rotor central shaft; the flange type stator end and rotor end can be connected from the slip ring. Lead out from the middle; the rotor end of the split conductive slip ring leads out from the shaft wall of the central shaft, and the stator end leads out from the brush holder on the side.

The above information is for reference only. If necessary, it is recommended that you consult professional technicians.

According to the overall structure and design of the slip ring, conductive slip rings can be divided into many types, including through-hole conductive slip rings, cap-type conductive slip rings, miniature conductive slip rings, insert-type conductive slip rings, and hollow shaft conductive slip rings. , separated conductive slip rings, disc conductive slip rings, wind power conductive slip rings, fiber optic conductive slip rings, high frequency conductive slip rings and mercury conductive slip rings, etc. Each type of slip ring has its specific application and performance characteristics.

In practical applications, the maximum current allowed by a conductive slip ring is determined by comprehensive factors such as the cross-sectional area of the conductive ring, the brush contact area, the pressure of the brush and the contact surface, and the rotation speed. Exceeding this safe operating current value may cause slip ring heating, contact surface fire, or other damage. Therefore, when selecting and using a conductive slip ring, it should be ensured that it operates within safe operating parameters and is supplied to the slip ring manufacturer based on the actual maximum current used.

- What are the contact methods for rotating conductive slip rings?

-

- 17-11-2023

- The contact mode of the rotating conductive slip ring is mainly achieved through sliding contact. The interior of the conductive slip ring is made of conductive

- more+

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE