What is the purpose of electric slip ring?

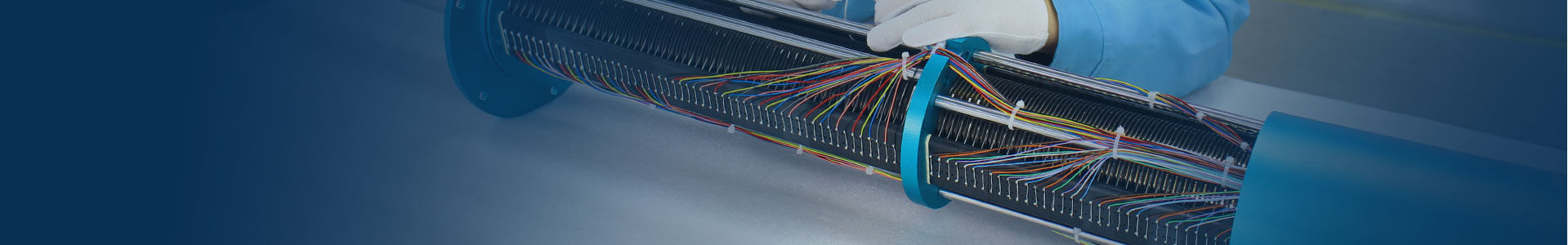

Electric slip ring is used to connect rotating equipment with stationary power sources. It allows the transmission of electrical power and signals from a stationary source to a rotating device,such as a motor or generator, without the need for a physical connection that would rotate with the device. This is achieved by using a set of metal rings that are insulated from each other and

connected to the stationary and rotating parts of the system. As the rotating part turns, the rings slide against each other, allowing the flow of electricity through them. Slip rings are commonly

used in industrial machinery, robotics, and other applications where rotating equipment needs to be powered or controlled.

The purpose of an electric slip ring is to enable the transmission of electrical power, signals, data, or other electrical currents between a stationary structure and a rotating part. This is accomplished

by providing a continuous electrical connection across a rotating interface without the need for hard-wired connections.

Key Purposes and Functions:

Continuous Rotational Power Transmission: Electric slip rings facilitate the transfer of electrical power from a stationary power source to a rotating component, allowing for uninterrupted operation of

motors, sensors, or other electrical devices on rotating equipment.

Signal and Data Transmission: They enable the passage of various signals and data between stationary and rotating parts, supporting applications such as rotary sensors, instrumentation, communication

systems, and feedback control in rotating machinery.

Rotating Sensors and Instrumentation: Slip rings provide a means to connect and power sensors, transducers, and other measurement devices mounted on rotating parts, ensuring continuous monitoring and

control of critical parameters without the hindrance of tangled wires.

Rotating Lighting and Heating Elements: In certain applications, slip rings are used to power lighting elements, heating systems, or other electrical components mounted on rotating structures, ensuring consistent

operation without the constraints of fixed wiring.

Industrial and Automation Equipment: Electric slip rings are integral to a wide range of industrial machinery such as wind turbines, rotating cranes, index tables, cable reels, and various automation

systems where continuous rotation and electrical connectivity are essential.

Advantages:

Uninterrupted Rotation:Capsule slip rings allow for 360-degree continuous rotation without the limitation of cables getting entangled or twisted.

Reduced Wear and Maintenance: By providing a reliable and low-friction electrical connection, through hole slip ring with flange reduce wear on cables and minimize maintenance requirements

associated with traditional wired connections.

Flexible Configuration: They can accommodate multiple channels for transmitting power, signals, and data simultaneously, offering flexibility for complex electrical needs in rotating systems.

In summary, electric slip rings serve the critical function of maintaining electrical continuity between stationary and rotating components, enabling the seamless transmission of power, signals,

and data in a wide array of industrial, automation, and rotating machinery applications.

For more details on slip ring products, please view :https://www.senring.com/signal-slip-rings/

FAQ questions:

1.What are the drawbacks of slip rings and carbon brushes?

2.What is the use of through bore slip ring?

3.What is difference between slip ring and split ring?

4.What is capsule slip ring and is used for?

5.What is the difference between a collector ring and a slip ring?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE