What is the working principle and maintenance method of servo motor encoder slip ring?

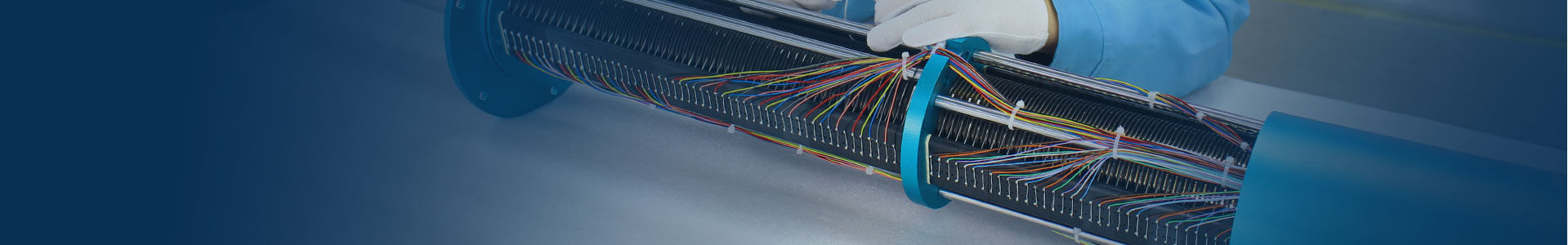

The servo motor encoder slip ring is a rotary joint used to transmit signals and data, which allows the motor to rotate without affecting the transmitted signals.The servo motor encoder slip ring is a device used to convert the rotational motion of the servo motor into an electrical signal. It usually consists of a set of slip rings and an encoder. The slip ring is fixed on the shaft of the servo motor, and the encoder is connected to the motor shaft through the slip ring.

When the servo motor rotates, the slip ring rotates with it, transmitting the motor's rotational motion to the encoder. Encoders usually contain a set of optical or electromagnetic sensors inside to detect the rotation of the slip ring and generate corresponding electrical signals. These electrical signals are sent to the control system and used to control the movement of the servo motor.

Here's an overview of how it works and how to repair it:

1. Working principle

Signal transmission: The encoder slip ring transmits signals and data from stationary parts (such as the fixed part of the motor) to rotating parts (such as the motor rotor) via rotating contacts.

Internal structure: Its interior includes a fixed part and a rotating part. The fixed part is connected to the equipment, and the rotating part rotates as the equipment rotates.

Contact method: Contact or non-contact signal transmission is usually used to ensure stable signal transmission.

Maintenance: Maintaining good electrical connections and contacts is the key to ensuring normal operation. Regular cleaning and lubrication of the slip rings is also necessary.

2. Maintenance methods

Cleaning: Clean contact surfaces regularly to ensure that no accumulated dust or dirt affects signal transmission.

Lubrication: If contact transmission is used, an appropriate amount of lubricant needs to be added at specified intervals to ensure smooth rotation and reduce wear.

Inspection: Regularly check the contacts for wear or damage. If there is any problem, replace or repair it in time.

Maintenance: Follow the manufacturer's recommendations and perform regular care and maintenance as directed.

Check for encoder failure: If the encoder fails, it may result in the inability to correctly detect the rotation of the motor. If the encoder fails, it needs to be replaced with a new one.

Check the control system: If the control system fails, it may result in the inability to correctly control the movement of the servo motor. If the control system fails, the circuit and software of the control system need to be checked and the failure repaired.

It should be noted that the maintenance of the electric slip rings requires professional technicians. If you are not sure how to perform the repair, it is recommended to contact a professional repairman or the manufacturer for repair. In general, the maintenance of the servo motor encoder slip ring is very important. It requires regular cleaning, lubrication and inspection to ensure stable signal transmission and extend its service life.

FAQ question:

1.How to install through-hole conductive slip ring?

2.What are the application fields of industrial bus slip rings?

3.What is the principle of high current conductive slip ring?

4.What is the service life and reliability of high-speed slip rings?

5.What is the function of through-hole conductive slip rings?

RESOURCES

RESOURCES GET A QUOTE

GET A QUOTE